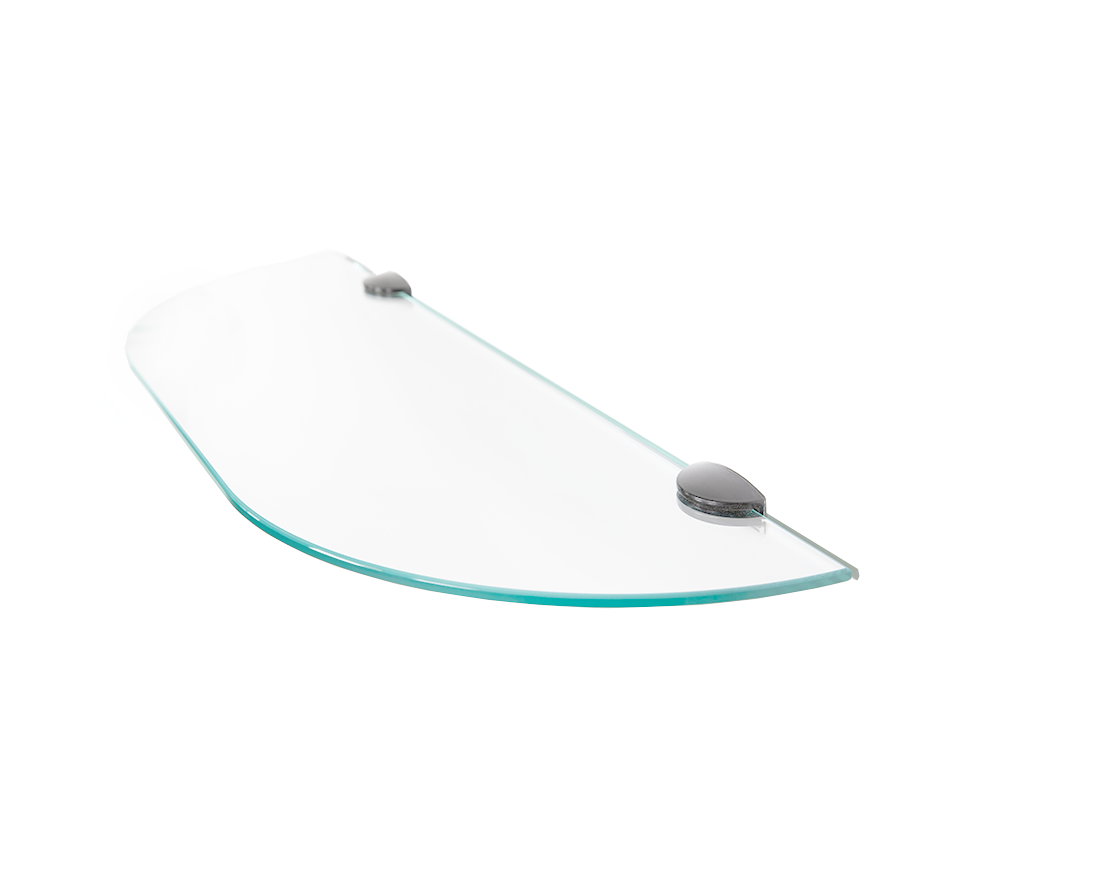

Polita dreapta

Politele din sticla drepte sunt piese plate realizate din sticla. Sunt utilizate in diverse aplicatii, cum ar fi mobilier, pereti de compartimentare, podele sau chiar in constructii. Politele din sticla drepte sunt disponibile in mai multe grosimi si dimensiuni, si pot fi personalizate in functie de necesitatile specifice ale fiecarei aplicatii. De asemenea, acestea pot fi laminare, pentru a spori rezistenta la zgarie-nori si socuri, sau pot fi acoperite cu diferite materiale pentru a imbunatati performanta estetica sau pentru a asigura proprietati suplimentare, cum ar fi izolarea termica sau fonica.

Lumina naturala

Design Modern

Economic

Durabilitate

Responsabilitate pentru mediu

Feronerie Germania

Procesul de fabricare al politelor din sticlă poate varia în funcție de producător și de specificațiile produselor, dar în general, urmează acești pași:

Pre-procesare: Sticla este tăiată la dimensiunile dorite și se curăță pentru a se îndepărta orice impurități sau praf.

Formare: Sticla este pusă într-un dispozitiv de formare, cum ar fi o formă sau o mașină de termoformare, care o întinde și o modeleaza în forma dorită.

Tăiere și finisare: După formare, sticla este tăiată la dimensiunile finale și se finisează prin șlefuire sau prin slefuirea marginilor pentru a se elimina orice asperități sau burți.

Controlul calității: După procesul de finisare, politele din sticlă sunt inspectate cu atenție pentru a se asigura că sunt fără defecte și că se potrivesc cu specificațiile tehnice.

Ambalare și expediere: După ce au trecut cu succes controlul calității, politele din sticlă sunt ambalate în siguranță pentru a se proteja împotriva zgârieturilor sau a altor daune în timpul transportului și sunt expediate către client.

Acesta este un proces general de fabricare al politele din sticlă. Unele produse pot necesita etape suplimentare, cum ar fi decuparea unor desene sau aplicarea unor finisaje speciale, în funcție de designul și de specificațiile produsului.